If you are new to THERMOMASS and insulated concrete sandwich panel construction, there’s a lot of information to take in. Here we hope to give it to you in a nutshell.

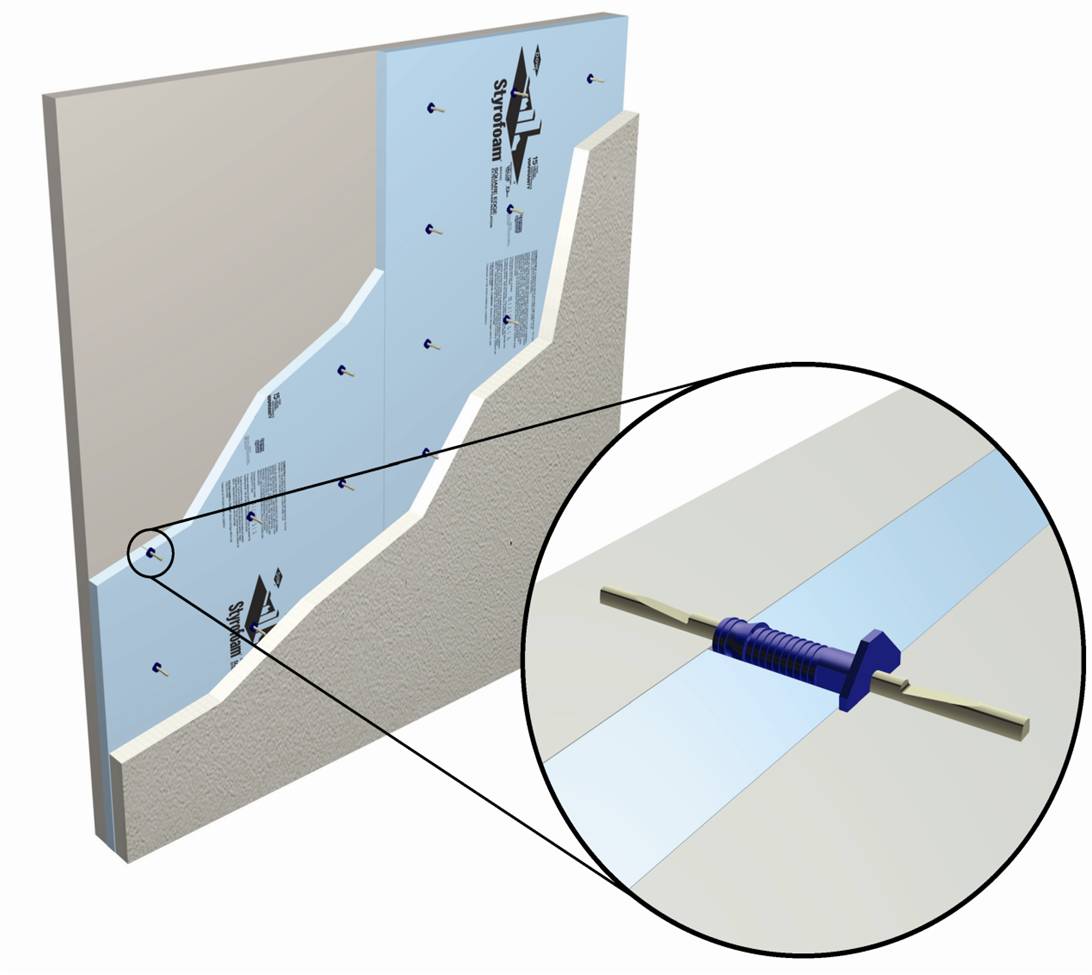

THERMOMASS XPS insulation, the fibre composite connectors, in combination with two layers of concrete, creates a thermal envelope with a high thermal mass. This insulated thermal inertia helps reduce the requirements for heating and cooling and therefore the annual cost of electricity.

|

|

|

THERMOMASS gives you a range of R-values depending on which Climate Zone you are looking for.

THERMOMASS’s greatest strength is the way it places high levels of thermal mass on the inside of the insulated concrete envelope. Doing so causes the diurnal swings to greatly reduce, levelling out discrepancies between peak and trough temperatures and greatly increasing the performance of the building. The bigger the swing, the more dampening effect the mass has. For a more comprehensive understanding of the way THERMOMASS lets your building utilise its high level of thermal mass – read this article.

TYPICAL DETAILING – For information about how various construction elements are constructed in a THERMOMASS building.

CASTING PROCESS – A two-stage concrete pour for tilt-up panels (face lifting). Same process for precast panels (edge lifting) but with option of which section to pour first.

Call us regarding your project and how THERMOMASS Makes Concrete Make Sense. For a 5 minute video summary, including thermal bridging testing footage – see the video page.